What Is a Tungsten Alloy Nozzle and What Are Its Applications?

In advanced engineering and production, the need for precise parts able to perform well in harsh conditions cannot be overstated. Of all these parts, the tungsten alloy nozzle deserves special mention because of its outstanding ability to handle high-temperature, long-wearing, and high-stress operations. This specific technical treatise aims to provide a working definition for a tungsten alloy nozzle and the benefits it derives from its materials and discuss the general applications it can handle.

1. Introduction to Tungsten Alloy Nozzle and its Special Materials

In context to the topic, a tungsten alloy nozzle is a type of specially designed nozzle made up of heavy alloys of tungsten that is used to control fluids or gas under a severe environment. Unlike the properties of other materials used to make a nozzle, steel or ceramic materials, the properties of a tungsten alloy nozzle possess a combination of density, thermal stability, and mechanical strength.

Nozzle materials made of an alloy of tungsten, along with additives like nickel, iron, or copper, improve machinability. However, adding these materials does not affect the benefits, which are its high melting point of around 3422°C and its higher density of around 18g/cm³. The combined material has a number of superior properties, which are a good fit for a nozzle as it helps it withstand severe conditions, as it has resistance to thermal shock, abrasion, and ductile rupture.

2. Key Features of Tungsten Alloy Nozzle Materials

Resistance to High Temperature and Stability

One of the major strengths of the nozzle material of tungsten alloy is the ability to withstand higher temperatures with structural integrity intact. The presence of gases at higher temperatures or even when working with molten metal would cause common metal solids to soften or fail. This is not the case with the nozzle material of a tungsten alloy because of the higher melting point that comes with the use of the metal tungsten.

Superior Wear and Abrasion Resistance

The industrial processes that entail the use of abrasive media, such as powder streams or high-velocity particulates, tend to wear out the common nozzle quickly. The wear resistance properties of tungsten alloy nozzle materials tend to be much higher compared to steel alloys. The reason for the popularity of the former lies in the significantly higher wear-resistant properties, which make it extremely desirable for customers looking to procure longer-lasting components.

Outstanding Mechanical Strength and Thermal Shock Resistance

The materials used in the alloy nozzles have a high strength and toughness. They are able to withstand forces and impacts that otherwise could cause a fracture of the material, which could result in a deformation of a softer material. They also have a good strength to thermal shock, meaning that they are able to withstand temperature shocks that otherwise could cause the material to crack.

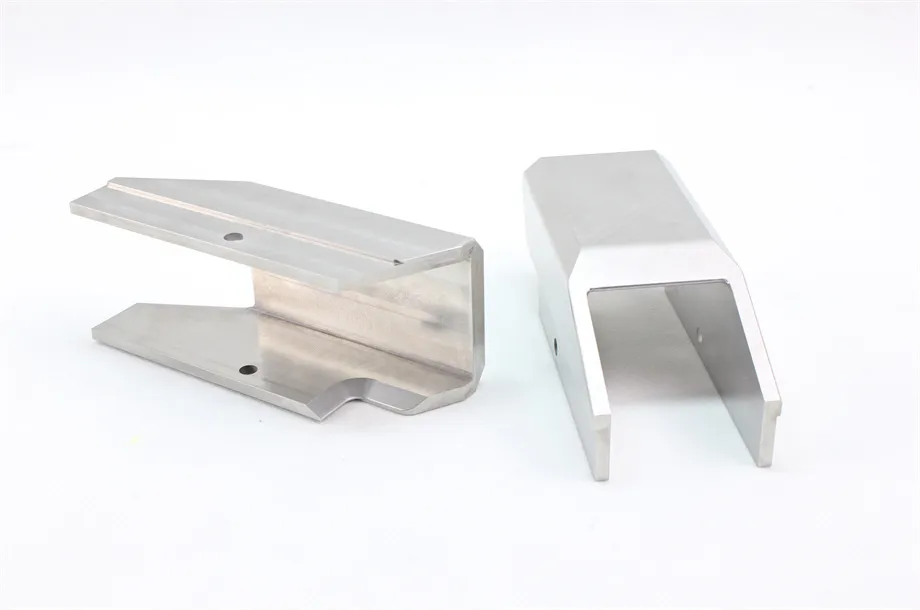

Precision Machinability for Custom Solutions

Although the tungsten alloys used to manufacture nozzles are difficult and dense as far as the state of matter is concerned, they can be machined to precise specifications. This is important because the ability to produce nozzles that fit precise flow control specifications enables producers of such nozzles to meet the required specifications. Regardless of the shape of the orifices required by the application, the nozzles can be manufactured accordingly.

3. Applications of Tungsten Alloy Nozzle in Key Industries

Aerospace and Defense

The aerospace industry requires highly capable materials in terms of performance in extreme environments; examples include rocket propulsion systems and gas nozzles in jet engines. Tungsten alloy nozzles are also often used in applications involving high temperature gas or fluid streams because of their reliable performance in controlling the flow in extreme environments. This combination of properties qualifies them for aerospace applications in which reliability can neither be compromised nor afforded.

Industrial High-Temperature Processing

There are several industrial processes that entail high-temperature processes. These include thermal spraying, metal cutting, and welding. Under such conditions, tungsten alloy nozzles are reliable. Thermal spray processes use tungsten alloy nozzles that guide melted particles to surfaces. Their use in thermal spraying could lead to increased efficiency since they can withstand high temperatures and abrasive particles.

Additive Manufacturing and Powder Metallurgy

Additive manufacture (3D printing) and powder metallurgy involve the flow of metal/ceramic powders of high precision. Tungsten alloys and their components like tungsten alloy nozzles are essentially required to control the flow of powder/gas while soldering the powders. The tungsten alloys are non-blocking and non-wearing components that prevent interruption of the flow of powders/gas stream while deposition/sintering.

Semiconductor and Surface Engineering

Deposition methods used in the semiconductor industry include highly controlled processes like chemical vapor deposition (CVD) and physical vapor deposition (PVD). Tungsten alloy nozzles are used as essential parts of the components used in the mentioned deposition procedures. The purity and inherent properties of the material used in the production of the tungsten alloy nozzles facilitate the semiconductor processing requirements.

Energy, Oil & Gas, and Other Specialized Sectors

In addition to the aforementioned applications in the manufacturing and aerospace industries, other areas that employ tungsten alloy nozzles include the energy industry, where oil and gas production equipment requires the handling of abrasive slurry and corrosive fluids. The reduced wear and advanced strength properties make field equipment much easier to maintain. Specialized cleaning equipment involving high-pressure water jets uses tungsten alloy nozzles due to their wear-resistant properties.

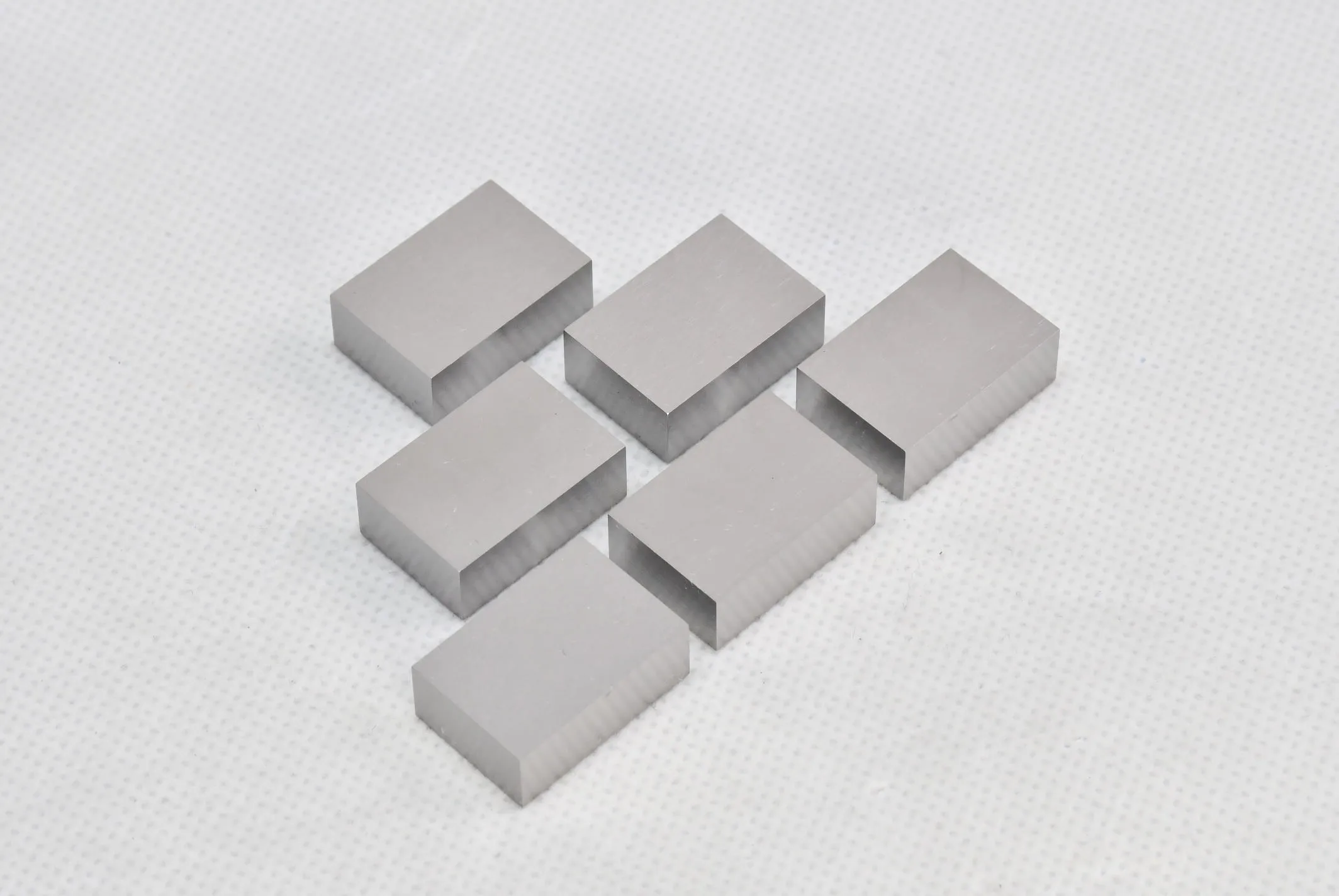

4. Product Feature: High Temperature Tungsten Alloy Nozzle

Jiuding provides our customers with a high-temperature tungsten alloy nozzle that is used in high-performance operations in which a normal nozzle cannot withstand the required conditions. The high-performance nozzle is one example of an advanced material used in the production of nozzles.

Made out of optimum quality tungsten heavy alloy, the nozzle provides:

- Resistance to extreme temperatures, which make it useful in applications like thermal spraying, gas flow involving high heat, and space technology.

- Enhanced wear and abrasion resistance, leading to longer operational life and reduced replacement frequency.

- Mechanical ruggedness to withstand vibration, impact, or mechanical stress without failing.

- Customizable dimensions and configuration as per engineering requirements.

5. Why Choose Tungsten Alloy Nozzle Materials from Jiuding

Being a seasoned exporter of tungsten alloy products, Jiuding has ample knowledge and expertise in manufacturing, as well as strict control over their products’ quality. The company's production of tungsten alloy nozzle material utilizes advanced knowledge in metallurgical processes to assure high functionality and reliability. Whatever the requirements of their clients, be it in standard nozzle manufacturing or in customized products, this company is always ready to serve international needs.

Purchasers benefit from:

- High quality assurance to ensure material and dimension integrity

- Customization services for meeting application-specialized requirements

- Delivery experience and international exporting experience, assisting in efficient international procurements.

- Technical assistance for help with the usage and application of the materials

6. Conclusion

An alloy nozzle made from high performance tungsten alloy nozzle materials can be critical in high temperature resistance applications. Whether it be aerospace industries, processing industries, three-dimensional printing, semiconductor devices, these high temperature alloy nozzles will function in the most challenging environments. For procurement managers or businessmen in search of nozzles with high temperature resistance properties, the high temperature tungsten alloy nozzles offered by us would be an attractive proposition designed to tackle the most demanding requirements of industries all over the world.

❓ Frequently Asked Questions (FAQ)

1. Why are tungsten alloy nozzle materials better than the usual nozzle materials?

The materials used in the nozzles made of tungsten alloy are more resistant to higher temperatures, provide better wear resistance, and possess increased strength than the materials used in nozzles made of steel metal.

2. Do tungsten alloy nozzles meet requirements for specific uses?

Yes, it is possible to precisely machine a nozzle made of a tungsten alloy to suitable dimensions and geometry as per industry specifications.

3. In what type of industries are tungsten alloy nozzles generally applied?

The application of the alloy in the form of a nozzle has many usages, ranging from aerospace to industries that have to process at a high temperature, three-dimensional printing, semiconductor devices, to the energy industry.

4. How does high temperature affect the performance of a tungsten alloy nozzle?

High temperatures can degrade many materials, but tungsten alloy nozzle materials maintain structural integrity and resist deformation or oxidation, ensuring long‑term reliability.

5. Where do I get quality tungsten alloy nozzles for export?

High-quality tungsten alloy nozzles, including "high-temperature" models, can be sourced from reliable suppliers such as Jiuding. They provide both regular models and customized versions.

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU